FORTUNA SKIVING MACHINES

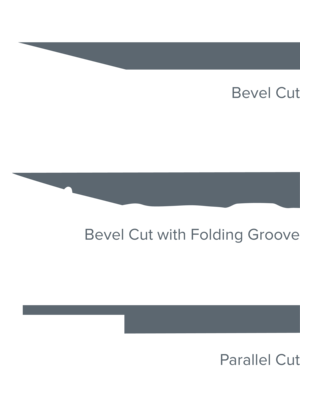

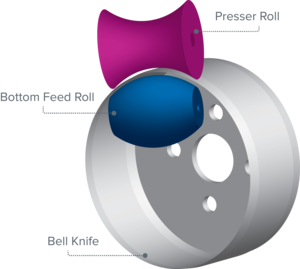

Skiving machines remove excess material, usually along the edge or edges of a part. Skiving is often used in the leather goods, automotive and furniture industries to bevel the edges of parts that will be turned over and glued to form a finished edge.

Hudson Cutting’s Fortuna line of simple bench-top skivers range from single-speed clutch motors and bottom-driven roll feed to more powerful dual (top and bottom) driven rollers for heavy-duty materials, together with separate electronically controlled knife and feed motors for maximum flexibility. Some sophisticated models include special steel stands and vacuums to collect dust and waste. Skiving machines can process cut widths up to 50mm (~2”).

Many of the Hudson-Fortuna splitting and skiving machines are automated to store programmable parameters for cutting thickness, angle and width to ensure production flexibility and quality independent of the user. All are designed for efficient, ergonomic operation.

Looking for something different?

Check out the Hudson Cutting Family of Skivers.

Learn More About Our Fortuna Skiving Machines

Fortuna 50-KK-S

The Fortuna 50 KK-S is a stiffener skiving machine with an upper driven feed roll. It is ideal for leather toe puff and counter, insole, shank, cardboard, felt and synthetic applications.

Fortuna 50-KS-G

The Fortuna 50 KS-G is a rubber skiving machine with an uppder driven feed roll and water box with sponge. It is ideal for rubber and smooth synthetics.

Fortuna ES-50

The Fortuna ES 50 is a single-scarf machine for skiving working widths up to 50mm. Featuring a step-less electronic drive of the feed roll, the ES 50 is ideal for shoes, leather goods and orthopedic industries.

Fortuna NG3

The Fortuna NG 3 is a network compatible multiple skiving machine for universal use in the shoe and leather industries. Computer programming is on the Windows operating system.

Fortuna NG6

The Fortuna NG 6 is a network compatible multiple skiving machine for universal use in the shoe, leather and automotive interior industries. Computer programming is on the Windows operating system.

Fortuna SM-50

The Fortuna SM 50 is a single scarf upper leather skiving machine with guide foot working width up to 50mm (NOTE: head only – required work table with friction clutch motor to be provided by the end user).

Fortuna VN-50

The Fortuna VN 50 is a single scarf upper leather skiving machine with guide foot working width up to 50mm (NOTE: head only – required work table with friction clutch motor to be provided by the end user).

Basic Skiving Operations